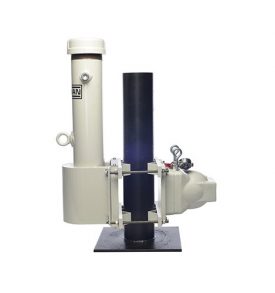

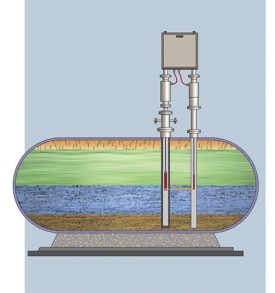

Ronan’s Radiometric Continuous Level Measurement System utilizing either the X96S or X96SI/R Transmitter accurately measures liquids or solids contained in a vessel, even in the most complex processes.

Radiometric Measurement provides a safe and efficient, non-contact method to measure liquids or solids in industries including:

- Mining and Aggregates

- Power

- Refining, Oil and Gas

- Chemical

- Metals

- Cement

The system can accurately measure process materials that are caustic or corrosive, abrasive or highly viscous, held at extreme temperatures or under high pressure, or contained in a vessel with an internal obstruction.

Manufactured by![]()