Description

The Fuji Electric Portaflow-C Ultrasonic Flow Meter is a compact and light-weight flow meter, offering high performance and easy operation for the noninvasive measurement of flow rates in pipes.

Utilizing the latest electronics and digital signal processing technologies, the Portaflow-C offers high accuracy, quick response time, and outstanding anti-bubble characteristics. In addition to standard flow measurements, the Portaflow-C is capable of heat quantity measurement allowing simple management for heating and cooling applications.

The Portaflow can be used with various types of detectors applicable for small to large diameter pipe and low to high temperature. This flow meter is designed for 12 hours of continuous operation with its own built-in battery which is rechargeable in 3 hours with the supplied power adapter. An SD memory card allows flow, velocity and total data to be stored for later recall. A universal USB port permits communication with a PC to facilitate configuring the Portaflow-C as well as saving and reading data files, and a 4.7 inch color graphic display creates an easy-to-use operator interface.

The Fuji Electric Time Delta-C ultrasonic flow meter is the latest generation of high-performance ultrasonic liquid flow meters using transit time technology. It is particularly effective in applications where high accuracy is required and the flow meter needs to be installed without shutting down the process. It is the perfect option for measuring flow rates of relatively clean, homogeneous liquids in closed, filled pipes.

The Time Delta-C uses advanced digital signal processing technology to provide a compact, lightweight solution with accuracies that are better than ±1% of flow rate with minimal influence by the pressure or temperature of the measured fluid. It offers best-in-class anti-bubble performance, which allows for accurate readings with air bubble content as high as 12% volume at 3ft/s velocity.

The rugged construction makes it ideal for installation in internal and external environments where IP66 (NEMA 4X) protection is required and it is 2/3 the size of its predecessor, the Time Delta-S.

Configuration is simple and intuitive via push buttons on the front panel. Alternatively, free PC compatible software is available, allowing multiple configurations to be stored and downloaded from a PC to the meter. Real-time trending and data logging, as well as diagnostics, can be performed with the loader software. The software also includes a sensor spacing calculation tool. A selection of outputs which include 4-20mA, transistor outputs, and RS485 (Modbus) are available for when flow rates and totals need to be transmitted.

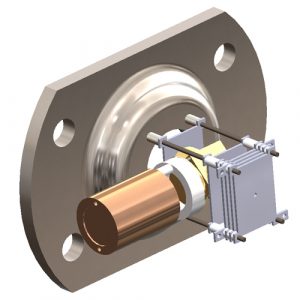

The Time Delta-C requires clamp-on sensors. These sensors clamp to the outside of pipes and cover pipe diameters from 13 to 6000mm (0.5 to 235 inches) at liquid temperatures from -40 to 200°C (-40 to 390°F). The system requires a straight pipe run of 10x and 5x pipe diameters upstream and downstream respectively.

TRANSIT TIME ULTRASONIC FLOW METERS The Technology Explained

Transit Time ultrasonic flow meters such as the Time Delta-C are well-suited for relatively clean fluids with low to moderate aeration. These meters operate by comparing the time for an ultrasonic signal to travel with the flow (downstream) against the time for an ultrasonic signal to travel against the flow (upstream). The difference between these transit times is proportional to the flow, and the flow meter converts this information to flow rate and total. With this technology, the transducers are mounted on the outside of the pipe, providing tremendous advantages over more traditional and invasive flow measurement instruments. This product is virtually maintenance free.