Description

OEMs and system integrators need to be able to react quickly to customer needs while maximizing resources. Whether replacing an existing product or designing a new process, the design of the EPack™ power controller has been carefully considered for fast and easy panel installation, commissioning and integration into wider systems, lowering equipment costs, and manufacturing times for you and your customers.

End Users continually need to improve operational efficiency and productivity. EPack power controllers can deliver real savings, significantly reducing your energy costs. Get the best from your operations; quick and easy to install, integrate and commission. A compact size doesn’t compromise powerful and versatile features that minimize costs and improve productivity and quality.

EPack 3-PH is the ideal solution for the control of all kinds of loads. The control of each phase ensures accurate control, even if the loads are unbalanced). The currents and voltage measures also allow a high level of diagnostics, which can be used for alarm management as well as monitoring (impedance, energy counter, reactive power).

EPack 2-PH is the latest generation of power controllers designed to be a cost effective solution for the control of 3 phase loads. The 2 leg control is particularly adapted to the control of balanced loads, directly, or through transformers. Burst firing avoids generation of harmonics and reduces the consumption of reactive power.

EPack 1-PH power controllers are designed to carry currents from 1 to 125 amps, with operating voltage between 100 and 500 Volts

The scalability and configurability of EPack fits with the requirements of each application. A wide range of alarms can quickly identify a controller detected fault which reduces downtime.

Key Features:

- Nominal load current from 1 amp to 125 amps

- Voltage up to 500V

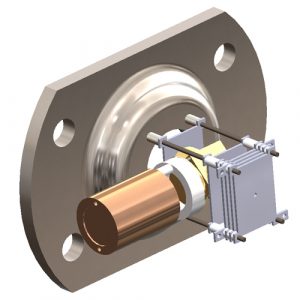

- Compact DIN Rail and bulkhead mounting

- Configurable via front panel or Eurotherm software (iTools)

- Plug and play Ethernet communications with Zero configuration networking (zeroconf)

- V2 , I2 or True power control

- Controls comprehensive range of loads: resistive, infrared, transformer primary, silicon carbide

- Energy usage measurement

- Advanced load diagnostics

- Integrated dual port Ethernet switch for “daisy chained” communications

- Modbus® TCP or Ethernet IP protocols

- Defend OEM knowledge and IP (OEM Security)

Documentation

Eurotherm Product Selection Guide (HA029395USA Issue 8)![]()