Description

IP71: Intrinsically Safe Current to Pressure Transducer

Performance

The IP71 transducer converts a current signal to a proportional pneumatic output. Using closed-loop pressure feedback circuitry, it provides precise, stable pressure outputs to final control elements.

Immunity to vibration or mounting position, high tolerance to impure air, and low air consumption make this unit ideal for demanding applications.

The compact housing, accessible ports and easy adjustments make it perfect for constrained spaces.

An integral volume booster provides high flow capacity, increasing control speed in critical applications.

The IP71 multifunction manifold provides a common air supply line to multiple IP71 units. Manifolds are available to hold 3 or 5 units.

Each port features a patented individual shut-off valve that allows safe on-line service or modification with supply pressure on. Individual units can be installed or removed without effecting other units on the manifold. Construction is simple and flexible.

Connection ports thread easily into IP71 units. No additional hardware such as a check valve or adapter kit is required.

The manifold has an optional DIN rail mounting kit. It can also be used as a common output manifold for solenoid valves.

FEATURES:

-

-

- Compact size

- Intrinsically safe

- Mount in any orientation

- Easy wiring

- Accuracy ±0.10% of span

- RFI/EMI protected

- I/O ports on front and back

- Supply pressures to 100 psig

-

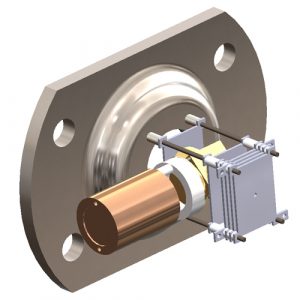

P81: Explosion Proof Current to Pressure Transducer

The IP81 explosion proof transducer delivers reliable high performance for the toughest applications in the most hazardous environments. Its NEMA 4X (IP65) housing is designed for both intrinsically safe and explosion proof operation.

Advanced circuitry includes electronic feedback control for superior vibration protection and highly accurate output. With flow rates up to 12 SCFM (20m3/hr), the IP81 has the muscle to drive large valves and actuators.

It is very economical to operate, consuming only 0.05 SCFM (0.11m3/hr), which is especially important in natural gas applications. An optional mounting kit lets you mount it directly on a valve, wall, panel, or 2” pipe.

Easy access Zero and Span adjustments make bench or field calibration quick and easy. For operating versatility, you can choose direct, reverse, and split range modes. A piezoelectric bimorph actuator and surface mounted electronics are conveniently mounted on a removable control manifold that allows easy maintenance.

Transducer Operation

The transducer uses a nozzle to control pilot pressure to an integral volume booster. The resulting output pressure is measured by a pressure sensor, which in turn provides a feedback signal to the control circuitry.

The feedback circuit compares this signal to the input signal and self corrects as necessary, minimizing the effects of vibration, position, temperature and supply pressure.

The current signal flows to the piezo actuator causing it to bend toward the nozzle, which restricts the flow of air through the nozzle and creates back pressure in the pilot pressure chamber. This back pressure acts as a signal pressure which in turn controls the pressure at the output.

FEATURES:

-

- Compact size

- Explosion proof

- Intrinsically safe

- Mount in any orientation

- Easy wiring

- Accuracy ±0.10% of span

- RFI/EMI protected

- Supply pressures to 100 psig

- NEMA 4X (IP65)

Documentation