Description

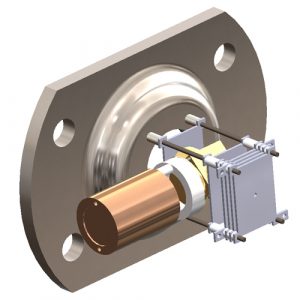

The VLM502 measures lengths and velocities without contact independently from the material and due to its comprehensive interfaces it can easily be integrated into automation and quality assurance processes in different industrial sectors.

The VLM502 works optically and contact-free. Based on a CCD sensor it implements the spatial filter principle. Spatial filter is the generic term for a measuring principle for the optical determination of velocity and length of moving objects.

The spatial filter is based on the filtering effect of lattice-like structures (grid modulation). Basically, the functional principle of the VLM502 can be described as follows: The illuminated measuring object is projected through lenses on the CCD sensor which acts as an optical grid. The VLM502 is equipped with a LED light source for the illumination. Due to the grid modulation a signal frequency, which is proportional to the speed, occurs upon movement of the object. The device calculates the velocity from the measured signal frequency. Several control circuits loops for an automatic adjustment to most diverse materials.

There are rarely requirements on the surface character of the measuring object. Precise measurements are facilitated on periodic structures as well as on stochastic surfaces of metals, wood, rubber or paper.

Advantages:

- Contactless

- Measuring range up to 50 m/s

- Measuring uncertainty ±0.025 %

- Working distance: 85 mm

- Slip-free

- Wear-free

- Material independent

- High power illumination LED

- No dangerous laser radiation

- Robust and precise

- Insensitive to contamination

- Economical

- Various interfaces

- Easy installation

- Easy maintenance

- PC software for parameterization

- 60-months warranty

- Quality product made in Germany

Documentation