Description

Models:

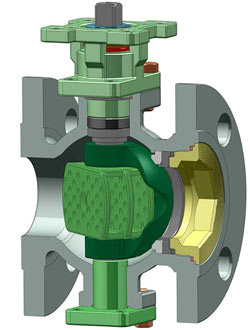

Series DM9900

Segmented Ball Valve, Flanged

Segmented Ball Valve, Flanged

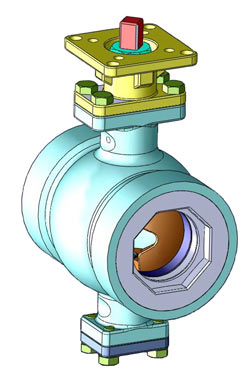

Series DM9900-W

Segmented Ball Valve, Wafer

Segmented Ball Valve, Wafer

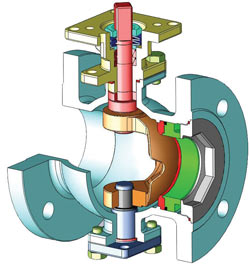

Series DM9900 J Trim

Anti-Cavitation Trim Live Loaded Segmented Valve

Anti-Cavitation Trim Live Loaded Segmented Valve

Series DM9900-W J Trim

Wafer Segmented & Anti-Cavitation V Port Control Valve

Wafer Segmented & Anti-Cavitation V Port Control Valve

-

Series DM9900

The J Trim option can help with liquid cavitation and aerodynamic noise problems. The pressure drop is divided into a series of small pressure drops and separates the flow stream into many small jet streams. This provides a combination of cavitation/noise abatement with high capacity, high rangeability and the capability to handle impure fluids.

DESIGN FEATURES

- Size range: 1-1/2″ – 6″

- ISO 5211 direct mount design

- ANSI Class 150, 300, 600, 900

- Flanged and flangeless versions available

- Live loaded packing

- Protected bearings, top & bottom

- Easy installation and versatility

- Standard ISA 75.04 face-to-face; optional: ANSI B16.10 short pattern

- Extremely low actuator torque

- J trim for cavitation/noise abatement

- WCB, 316SS, 317SS and other alloy materials available

- Metal seated

- Patented

Latest Product