Description

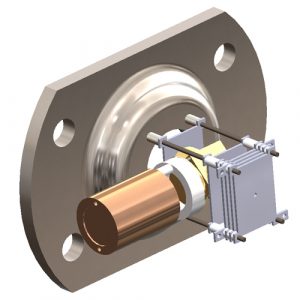

Final control elements in Emergency Shutdown applications such as ON-OFF, Blow Down and Venting Valves remain in one position over a long time without any mechanical movement. These valves have a tendency to get stuck and as a result may not operate on demand. This can have a severe impact on the functionality of a Safety System and could result in adverse conditions to operating personnel, plant equipment and the environment.

Partial Stroke Test reduces the frequency of shutdown for maintenance and offers operators a tool to easily identify the troubleshooting function of ESD valves. The test can be easily executed via the FDT-DTM based configuration and diagnostic tools VALcare and Valve Monitor. The test can also be requested by an SIS Logic Solver and the result of the test can be read by the Logic Solver. This architecture has been developed in conjunction with Triconex® and eliminates the possibility of human error while reaching a high level of safety as described by IEC 61508 and IEC 61511.

Benefits

PST reduces the frequency of shutdown for maintenance for ESD valves

PST Status through communication, LCD display and Digital Output

Online extended diagnostic through certified DTM in HART/ PROFIBUS PA/ FF

External SOV monitoring with pressure dip detection

Full Stroke Test monitoring with trigger capabilities

Applications

Online/Offline diagnostic critical process valves in Oil & Gas, chemical, Pulp & Paper and Power

Strong repair and maintenance tool for all process industry valves

Advanced configuration tool in pre-commissioning phases for Control valves

Partial Stroking Test set up and diagnostic software

Documentation

FD-AS-PO-002-EN![]()

FD-AS-PO-001-EN![]()