Description

Description

The result is a response matrix analogous to that afforded by the established, complex FTNIR analyzer, but with several anticipated benefits:

- Higher measurement precision for precise process control

- Continuous analysis (4 second measurement interval)

- Reduced complexity in sample handling for improved safety and reliability

- Extremely low maintenance improved for improved safety and reliability

- Dramatically lower expected cost of ownership Features

- An integrated analyzer system for installation in the alkylation unit

- Modular design for facile swap-out of measurement sensors and components

- Proven measurement technologies with an established history of service in HF applications

- Mounting of all components on an open panel to eliminate an enclosure where HF can accumulate

- All wetted parts associated with the analyzer system and sample handling are specified in the specific offering but are typically made with Hastelloy-C, Monel, Grafoil, Teflon®, Kynar and Chemraz®.

- Measurement is performed on sample flowing continuously through tubing and components half-inch, minimizing pressure drops that cause flashing of light hydrocarbons.

- Manual valves to isolate the analyzer system and purge with isobutane, alkylate, nitrogen, etc.

- Data logging and historizing of KPI’s will be done in the host DCS to enable quick and easy diagnostics.

- This is an HF process which is corrosive.

FEATURES / BENEFITS

- Non-spectroscopic measurement system designed to measure all components in HF alkylation catalyst: HF, water, and acid-soluble oils (ASO)

- Direct chemical measurement

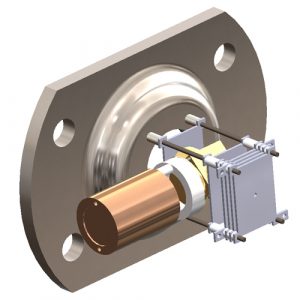

- An integrated panel-mounted system for installation in the alkylation unit

- All wetted parts associated with the system and sample handling are made with Hastelloy C,Teflon®, and Kalrez® (Cheraz®)

- Measurement is performed on sample flowing continuously through tubing and components half-inch or larger, minimizing pressure drops that cause may flashing of light hydrocarbons

- Continuous flow and pressure output to indicate proper operation

- Unaffected by sample temperature variation

- Manual valves to isolate the analyzer system and purge with isobutane, alkylate, nitrogen, etc.

- Modular design for easy swap-out of measurement sensors and components

- Utilizes proven measurement technologies with an established history of service in HF applications

- Internal data logging and historizing of KPIs to enable quick and easy diagnostics

- No wear elements requiring preventative maintenance

Documentation