Description

Improve separation efficiency, optimise production rates and minimise unforeseen shutdowns with pipe slugging characterisation.

The measurement and characterisation of process slugs is critical within the oil and gas industry. Greater control and suppression of vapour or liquid slugs, means that production rates are optimised, maintenance costs are reduced and unforeseen shutdowns are minimised.

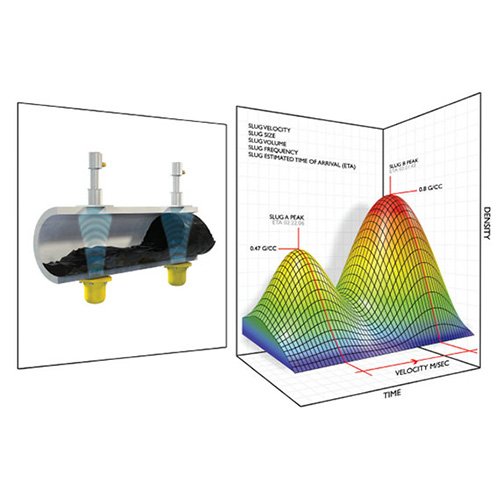

Real time slug characterisation

The Tracerco™ SlugMonitor is the first non-intrusive, real-time gamma transmission-based slug characterisation instrument. Using advanced measurement technology alongside sophisticated signal processing, Tracerco is able to offer the most accurate and reliable instrument capable of characterising process slugs.

The measurement and characterisation of process slugs enables the presence and frequency to be understood, in order that the process conditions can be changed to reduce their magnitude and detrimental effect on the separation train.

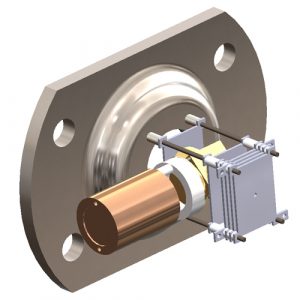

Custom designed

The Tracerco™ SlugMonitor is a unique, custom designed system to meet your measurement requirements. Particularly suited to aggressive process environments, the instrument is not susceptible to fouling or heat damage. It can be easily retrofitted and is backed up by our global service team whose engineers are highly experienced within the oil and gas industry.

The Tracerco™ SlugMonitor instrument can determine:

- Slug velocity

- Slug size

- Slug volume

- Slug frequency

- Estimated time of arrival

Benefits of the Tracerco™ SlugMonitor

- Certified for use in hazardous area zones 1 and 2.

- Real time analysis and historical trending data available.

- Aids separation efficiency.

- Wide operating temperature.

- Clamp on non-intrusive solution

Typical applications

Tracerco™ SlugMonitor is suitable for use in:

- Oil and gas pipelines

- Deepwater risers

- Steam Assisted Gravity Drainage (SAGD)