Description

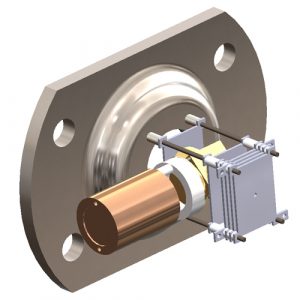

The HI 1769-FC Feeder Control module automatically calculates and adjusts tuning parameters typically required to maintain desired flow rates in a dispensing or filling system.

It is a microprocessor-based CompactLogix™ and MicroLogix™ 1500 plug-in module used with the PLCs Rack I/O in a variety of material-flow applications, such as auger, belt, and vibration-based feeders. It can be operated in batch, automatic, or manual mode.

Worry Free Operation

The HI 1769-FC feeder control module will watch your process and notify you of problems. Prompts on your system’s HMI display and PLC alarm relay outputs occur with tolerance errors and other failures.

Algorithms contained in the HI 1769-FC compare user defined flow rates to the actual flow rates by continuously monitoring changes in the system weight over short intervals of time; the 1769-FC then calculates the adjustments necessary to achieve the user defined rate and instructs the PLC to adjust the speed of the feeding or dispensing device.

The 1769-FC updates 100 times per second and is capable of 8 million counts of resolution, enabling the instrument to precisely determine target flow rates and tolerate large “dead” loads. The HI 1769-FC incorporates Hardy Process Toolbox core features WAVERSAVER®, C2® electronic calibration and INTEGRATED TECHNICIAN® (IT).

The 1769-FC updates 100 times per second and is capable of 8 million counts of resolution, enabling the instrument to precisely determine target flow rates and tolerate large “dead” loads. The HI 1769-FC incorporates Hardy Process Toolbox core features WAVERSAVER®, C2® electronic calibration and INTEGRATED TECHNICIAN® (IT).

Multiple Feeder Control

The HI 1769-FC is a powerful building block when it comes to multiple feeder systems. It can be a slave to other process inputs through the CompactLogix™ or MicroLogix™ 1500 processor.

Automatic Weight and Rate Calibration

A five-point auto rate calibration automatically allows the module to calibrate itself to the characteristics of the feeder and the material being fed. This allows for a higher feed accuracy over a broader range of feed rates.

Rockwell Add-On-Profile (AOP)

Quickly and easily configure the HI 1769-FC for your application through PLC software on a PC.

Documentation