- In pneumatic applications for material flow rates of up to 100 kg/h

(depending on application) - In free-fall with a drop speed of at least 2 m/s (approx. 25 cm drop height)

- In cases where dust measuring instruments cannot cope and flow rate

measuring instruments are overspecified

Continuous flow measurement at low solid/air ratios

Categories: Mass flow measurement, SWR engineering

Description

Use

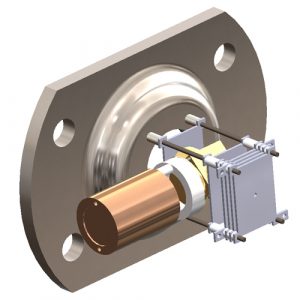

PicoFlow was specially developed for measuring powder flows in transport lineswith very low material concentrations.

PicoFlow is particularly good in pneumatic applications but will also work reliably in free-fall applications with drop speeds of at least 2 m/s.

The measuring system delivers absolute measurements (after calibration)

in g/h or kg/h.

Latest Product