Description

Up to 28 Channels of Weight on one SINGLE Ethernet Connection!

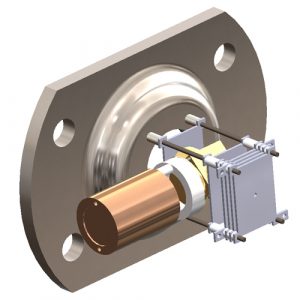

New HI 6600 Series Modular Sensor System

The new HI 6600 series is a modular system of weight processors that deliver up to 28 channels of fast, stable, high-resolution weight readings to PLCs, PACs and DSCs over a single fieldbus network connection.

Ideal for applications that require more than one channel of weight, such as inventory tank farms, batching systems and multi-head filling machinery; each channel of the HI 6600 processes signals from up to four connected load cells then outputs the entire system’s weight data over Ethernet TCP/IP, Modbus RTU, Modbus TCP and either EtherNet/IP or Profibus-DP, depending on the Hardy Gateway Module.

Ideal for applications that require more than one channel of weight, such as inventory tank farms, batching systems and multi-head filling machinery; each channel of the HI 6600 processes signals from up to four connected load cells then outputs the entire system’s weight data over Ethernet TCP/IP, Modbus RTU, Modbus TCP and either EtherNet/IP or Profibus-DP, depending on the Hardy Gateway Module.

SOLID PERFORMANCE

The HI 6600 enhances productivity of manufacturing systems by digitally suppressing noise and dramatically reducing scale settling time. Even in noisy environments with excessive amounts of mechanical vibration, the HI 6600 provides a steady 1:10:000 resolution in oz, lb, ton, g, and kg with 110 updates per second over its variety of communications protocols.

EASY INSTALLATION

Just snap the number of weight channels you need onto a DIN rail, cable the units together to the Gateway Module using standard Cat5e cable, connect sensors, power up and press DISCOVER. The system will automatically identify all the modules connected together and make them addressable for set-up and calibration through the PLC, embedded Webserver or optional display. A Rockwell EDS_AOP simplifies integration using RSLogix.

SIMPLE SET-UP & CALIBRATION

The embedded webserver enables access to setup and calibration from anywhere on your network. An optional display adds front panel

keys, simple menus and help text to make local control elementary. Use Hardy’s exclusive C2® for automatic system calibration to save hours in commissioning and routine maintenance.

QUICK MAINTENCE & DIAGNOSTICS

With INTEGRATED TECHNICIAN®, maintain and troubleshoot the weighing system from anywhere in the world or use Hardy’s intuitive local display that supports multiple languages. Store all the system parameters on a USB, clone settings between channels, and restore settings with the press of a button. Quick-disconnects on all wiring makes hot swapping damaged channels a snap!

OPTIONAL DISPLAY

Hardy’s big, bright display allows local set-up, calibration and troubleshooting of the weight system without the need to access parameters via a PC, PAC, or PLC. Basic monitoring and maintenance can be done by anyone through its IP66 rated keypad. The display can show weight from up to 28 connected weight modules, displaying up to 4 channels simultaneously. Name the weight channels for easy identification and arrange them to show in any order.

ULTRA LOW POWER CONSUMPTION

At just 1.72 watts of power per channel and 3.9 watts per Gateway Module, eliminate the cost of cooling in the control cabinet and create high-density cabinet designs to save space and money.

VIBRATION IMMUNITY

Hardy’s WAVERSAVER® supresses vibration and mechanical noise, dramatically reducing scale settling time and increasing the speed of stable weight readings.

Documentation