Description

APPLICATIONS

- Spool length measurement (web material, belt, conveyor material)

- Cut-to-length control

- Length measurement of discrete parts and goods in pieces

- Length measurement of incoming goods and issued goods

- Length measurement for waste reduction and production data acquisition

- Measurement of differences in length for process control (elongation; shrinkage)

- Accredited systems with EU qualification approval for non-contact length measurement according to MID 2014/32/EU (form. MID 2004/22/EC)

- Continuous, durable and endless length measurement

Examples

- Paper and cardboard (roll length, format length, …)

- Print industry (rolls, labels,…)

- Plastic and extrusion (foil, film, profile, tube,…)

- Textile (technical textiles, woven, non-woven,…)

- Carpet and flooring (rolls, goods in pieces,…)

- Metal (coil, sheet metal, tube, profile, wire, cable,…)

- Timber (veneer, timber pieces, plate,…)

- Construction and insolation material (web, rolls, plates,…)

- Cable and wire (rolls, pieces,…)

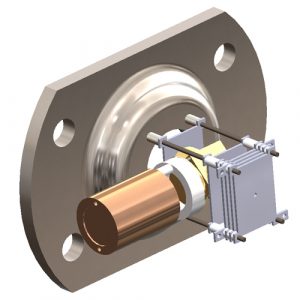

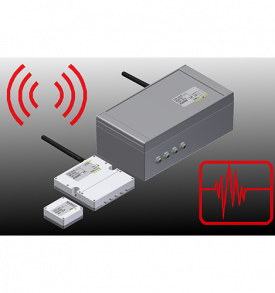

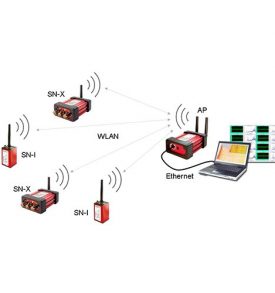

The µSPEED® product family is used for non-contact measurement of length and speed of a variety of moving surfaces such as web material, winded material and goods in pieces. µSPEED sensors replace contact wheels and other tactile measurement systems, which due to slippage, ageing or dirt built up, do not work reliably. µSPEED avoids the dependency of the measurement on the type of material, surface or thickness, or the injury of the surface of the material by traces or scratches. The optical length gauge µSPEED works on all types of materials, surfaces, structures and colours without parameter setting and independently from material and transportation conditions. Materials to be measured can be solid, smooth, dry or wet. They can be transported on conveyor belts, produced as web, tube or wire, can be endless or piece goods. Applications include the measurement of spool length, cut-to-length control, encoder calibration as well as production and process surveillance e.g. by measurement of differential speed. Production machines as well as inspection, winding and slitting machines can easily be equipped with µSPEED systems. µSPEED systems are both maintenance free and long-term calibrated. µSPEED systems are able to reach an accuracy of better than ± 0.1‰ at length or speed, which has to be measured. µSPEED systems, which are based on laser-doppler technology, set standards regarding size, ease of use and lifetime. µSPEED is available in a version, which is certified by the national metrological institution of Germany PTB (Physikalisch Technische Bundesanstalt) – now also according to MID (measurement instruments directive) 2014/32/EU standard (form. MID 2004/22/EC). A range of applications: Spooling, winding, roll winder, unwinder, slitter rewinder, short roll winder, re-reeler, sliding winder, cutting machine, cross cutter, sorting cross cutter, inspection machine, …

LENGTH MEASUREMENT COUNTER – MID-CNTThe

|

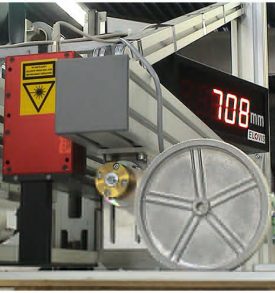

DISCRETE PART LENGTH MEASUREMENT – SLMThe SLM system is designed for highly accurate discrete part length measurement. With a resolution of 1/100 mm and an accuracy of better ± 1/10 mm (per meter), SLM is used for manual random sample testing as well as for 100 % inline length check during production or before sorting at material speed up to 4 m/s.

|