Description

HI 6300 Series of Weight Processors

HI 6310 Multi-Channel Display Saves Time, Space, Money

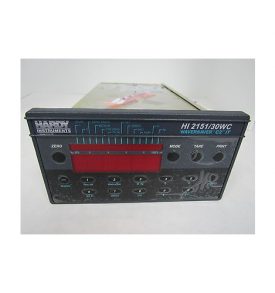

Have you ever stood across the plant floor straining to see your system’s weight on your controller’s display? Not anymore! The HI 6300 series of weight processors solves that problem with the easiest to read display in the industry! And they have a whole lot more.

For maximum visibility and usability, the HI 6300 series features a rugged high contrast display with a 140 degree viewing angle for easy reading. This high-definition display allows for easy to read messaging with no need to check a manual for error codes or instructions.

The HI 6310 model features a multi-channel display that can show the weight readings of up to four instruments on one panel simultaneously! Just one display can serve as an easy-to-use scale interface for all four connected instruments. Save money, space and time!

The HI 6310 model features a multi-channel display that can show the weight readings of up to four instruments on one panel simultaneously! Just one display can serve as an easy-to-use scale interface for all four connected instruments. Save money, space and time!

The HI 6300 Series includes the HI 6300 and the HI 6310. Both instruments are engineered to provide accurate, stable and repeatable weight, while striking the optimum balance between price and application flexibility.

The HI 6300 series can be used as a standalone weight processor or as the front-end to a weight-based control system. These instruments read, condition, and digitize load cell and strain gauge signals commonly found in process weighing applications, including inventory management, batching, blending, filling, dispensing, and check weighing. With a robust, ultra-low profile design and powerful weight processing features, they are an ideal solution for applications where fast, precise weight-based controls are critical functions of a process.

EASY SETUP!

A built-in set-up wizard guides you through installation and calibration or use the embedded web server in the HI 6300 series to set up all the parameters from anywhere on your network. Front panel keys and LCD display with simple menus enable quick,simple setup of parameters with help text displayed every step of the way. Designed for use worldwide, the HI 6300 series supports messaging in a variety of languages.

Use the Hardy Process Toolbox’s exclusive C2® or eCAL™ for automatic calibration of the weighing system, saving hours of start-up time.

Featuring Hardy’s famous WAVERSAVER® technology, the HI 6300 series ignores the effects of vibration and mechanical noise typically found in machine and factory environments. WAVERSAVER® dramatically reduces scale settling time while remarkably increasing the instrument’s output speed of stable Gross and Net weight readings.

Quickly and easily troubleshoot and isolate problems in your weighing system from the front panel of the display or connected control system using the Hardy proprietary INTEGRATED TECHNICIAN built-in system diagnostics.

INSTALLATION YOUR WAY

For panel mounting, simply drill five holes using the included template to mount the keypad/ display to the front and the instrument electronics to the other side of the panel. No more rectangular holes to cut! You can also remote mount the front panel up to 100 feet away. Just snap it onto a DIN rail or mount on a wall. Blind remote or 3wall mount configuration is also a snap. The Ultra Low Profile Design allows the HI 6300 series to fit in a 2″ deep cabinet!

Documentation

HI_6300_series_datasheet_0414![]()

HI6500dsheet0316![]()