Description

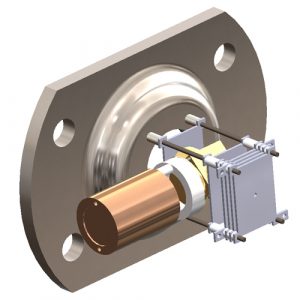

Hardy OneMount Load Points

OneMount HI ONELP Load Points with Advantage Lite HI SB05 Shear Beam Sensors

The Hardy OneMount™with Advantage® Lite shear beams are specifically built to  save customers time and money during installation, calibration, and maintenance. Each load point provides extraordinary flexibility and durability in most industrial environments. Each feature of the load point was intentionally designed based on nearly 100 years of process weighing experience, delivering a best-in-class measurement system for vessel, hopper and tank weighing.

save customers time and money during installation, calibration, and maintenance. Each load point provides extraordinary flexibility and durability in most industrial environments. Each feature of the load point was intentionally designed based on nearly 100 years of process weighing experience, delivering a best-in-class measurement system for vessel, hopper and tank weighing.

Accuracy

- Self-centering rocker design maintains alignment under considerable shear forces

- Precision sensor (combined error 0.02% rated output) from 1,125 lbs – 22,500 lbs

- Optional Dynamic Stabilization Rods can be purchased to reduce vibration noise on the sensor for better resolution

Safety

- Liftoff and side force ratings are confirmed by third party destructive testing

- Potted sensors provide economical options for installations that only require IP67 ingress protection

- C2® weightless calibration reduces the risk of accidents or contamination from test weights

Easy Installation

- Integral spacers can carry the full rated capacity without the load cell installed, eliminating the need for expensive dummy load cells or welding fixtures

- Once mounts are installed, the load cells slide into place. With minimal tank jacking (1/8”), the spacers are removed for a live load point

- 360° checking mechanism means load points can be installed in any direction

- C2® electronic calibration for fast startup in high capacity installations

Easy Maintenance

- Replace load cells with minimal tank jacking (1/8”)

- Matched mV/V/ohm load cells are easy to replace without recalibration

User Benefits

- OEE improvement from consistent, accurate performance, and reduced installation and maintenance time

- Reduced capital investment and labor typically associated with dummy load cells and welding fixtures

- Reduced complexity of system selection and installation from a single, universal design

Easy Installation Process

- Align and level the mounts under the vessel without the load cells installed. The mounts can be installed in any orientation, because of a 360º checking mechanism to ensure accuracy and safety.

- Lower the vessel onto the mounts and weld or bolt the mounts to the foundation and the vessel.

- Perform any peripheral pipe welding or add any required attachments.

- Slide the load cell into place and fasten to the bottom plate.

- Jack the vessel up 1/8” to remove the shipping/installation bracket.

- Lower the vessel onto the live load point and calibrate using Hardy’s C2® electronic calibration.

Documentation

OneMountShearB_HISB05(1)